There are two distinct and different requirements in ISO 13485:2016 for the management of risk.

From Dr John FitzGerald:

Misinformation about risk management is already too easy to find regarding the adoption of ISO 13485 in the FDA's QMSR regulations, which will come into force in February 2026. If you follow the advice of these self-appointed experts, you will likely become confused and perhaps implement a risk management regime for your company that is overly burdensome yet does not meet the standard's requirements. Here are the facts based on our experience working with this edition of the standard since it was published in 2016.

As the subheading says, ISO 13485:2016 has two distinct and different requirements regarding risk management.

- One relates to the management of the processes that make up the ISO 13485 Quality Management system, and

- The other relates to patient /end-user safety, that is, safety in manufacturing.

The difference between the two is often missed, especially by component manufacturers, as is the issue of patient safety. Let's consider what's required.

Risk-based Thinking and ISO 13485

Risk-based Thinking in Sub-clause 4.1.2 focused on threats to Quality Management System processes. t states:

The organization shall:

- determine the processes needed for the quality management system and the application of these processes throughout the organization, taking into account the roles undertaken by the organization;

- apply a risk-based approach to the control of the appropriate processes needed for the quality management system;

- determine the sequence and interaction of these processes.

Applying Risk-based Thinking to ISO 13485

There is no guidance in the ISO 13485 Standard as to precisely what's required. e, therefore, have a requirement analogous to that of ISO 9001 for risk-based thinking. We can find it in ISO 9001 Annex A4, a guidance section that states:

The concept of risk-based thinking has been implicit in previous editions of this International Standard, e.g. through requirements for planning, review and improvement.

This International Standard specifies requirements for the organization to understand its context and determine risks as a basis for planning.

This represents the application of risk-based thinking to planning and implementing quality management system processes and will assist in determining the extent of documented information.

Formal Risk Management Methods

Although ISO 9001:2015 Clause 6.1 specifies that the organization shall plan actions to address risks, formal risk management methods or a documented risk management process are not required.

The situation is identical in ISO 13485:2016 where, in Clause 4.1.2, it states: b) apply a risk-based approach to the control of the appropriate processes needed for the quality management system;

Organizations can decide whether or not to develop a more extensive risk management methodology than is required by this International Standard, e.g. through the application of other guidance or standards.

Not all the processes of a quality management system represent the same level of risk regarding the organization's ability to meet its objectives, and the effects of uncertainty are not the same for all organizations.

Under the requirements of Clause 4.1.2 b), the organization is responsible for applying risk-based thinking and its actions to address risk, including whether or not to retain documented information as evidence of its determination of risks.

Limitations of Risk-Based Thinking

The requirement, then, is to apply risk-based thinking to planning and implementing all QMS processes, with a view to more tightly controlling the more vulnerable processes from a product/service quality point of view.

Most manufacturing organizations choose to retain documented evidence of compliance (both for ISO 9001 and ISO 13485) and to introduce a formal Risk Management process, focused on threats to QMS processes, with documented risk management tools, which usually includes a variant of FMEA.

That deals with the requirement in sub-clause 4.1.2. The requirement in clause 7.1 is different and will not be adequately addressed with risk-based thinking or even risk management in planning and implementing all QMS processes.

Risk Management in Clause 7.1 focused on threats to patient/end-user safety

ISO 13485:2016 Clause 7.1, Planning of Product Realization, includes this sentence (our emboldening):

The organization shall document one or more processes for risk management in product realization. Records of risk management activities shall be maintained (see 4.2.5).

The wording here is very vague for such an important issue. At the end of clause 7.1, reference is made to ISO 14971 for guidance.

The introduction to ISO 14971:2019, Medical devices - Application of risk management to medical devices, is more helpful and tells us (again our emboldening):

As one of the stakeholders, the manufacturer reduces risks and makes judgments relating to the safety of a medical device, including the acceptability of residual risks. The manufacturer takes into account the generally acknowledged state of the art in order to determine the suitability of a medical device to be placed on the market for its intended use.

This (international standard) specifies a process through which the manufacturer of a medical device can identify hazards associated with the device, estimate and evaluate the risks associated with these hazards, control these risks, and monitor the effectiveness of the controls throughout the medical device's life cycle.

So, Clause 7.1 concerns' the safety in use of a medical device, including the acceptability of residual risks' and is not concerned with manufacturing processes (product realization) alone.

Risk management here is about applying risk management tools (many examples are given in ISO 14971) focused on threats to patient/end-user safety. The activities and records are closely related to the content of the Medical Device File (see clause 4.2.3).

Recommended Action When Implementing Risk Management and Risk-based Thinking to ISO 13485

ISO 13485 requires risk-based thinking regarding QMS processes (sub-clause 4.1.2) and risk management regarding patient/end-user safety when using medical devices (clause 7.1).

Ensure your management system distinguishes between the two and treats (and documents) their requirements separately. Otherwise, you may well have a major non-compliance at your next Certification Audit.

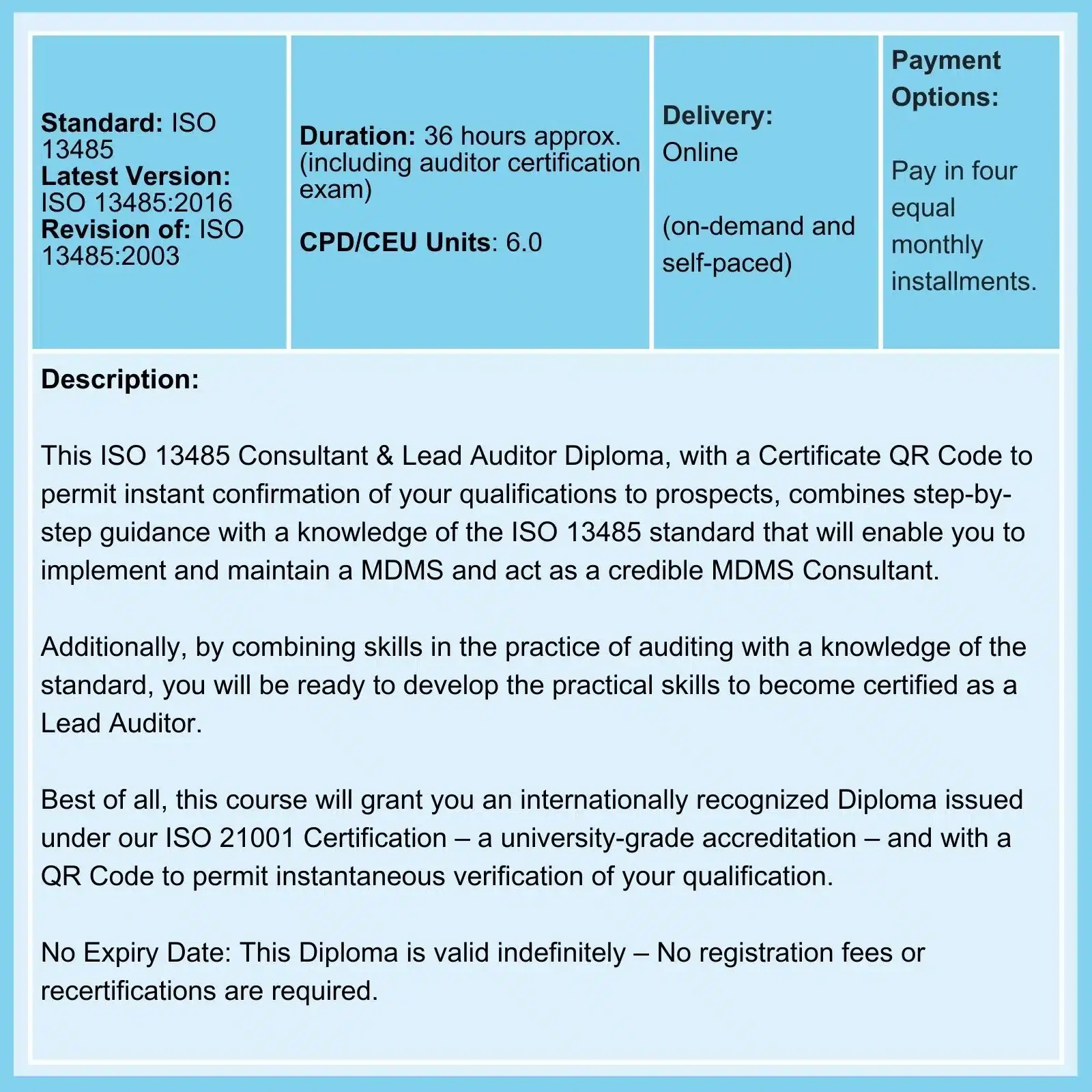

NOTE: The requirements here are covered in depth in our ISO 13485 Lead Implementer and other Courses.

Related Courses (ISO 13485 Implementation)

Related Courses